Projects

|

Client: NMPC --- Status: Ongoing |

|

Negin Mokran Development Petrochemical Co. (NMPC) has decided to develop a third hub of Petrochemical Industries in Chabahar Free Trade-Industrial Zone. Based on detailed investigation, 1,200 hectares of Chabahar Free Trade- Industrial Zone with dimensions of 2.7 × 4.4 Km has been allocated for petrochemical zone. Mokran Abniroo company "MAN" (a sub-company of NMPC), is willing to initiate the construction process of "Sea water Intake of MOKRAN Petrochemical Complex- Phase I" Project to supply 560,000 cubic meter seawater per day for desalination purposes. Delta Offshore Technology is appointed as EPC contractor of basic design endorsement, detail design engineer-ing, procurement, construction/installation and commissioning facili-ties of the seawater intake/outfall system. For construction of intake and outfall pipelines and to protect the environment and avoid delays due to harsh conditions of Oman Sea and hard layer of seabed, it was decided to install concrete pipes by microtunneling method. |

|

Client: MAPNA --- Status: Ongoing |

|

Qeshm combined cycle power plant which is under construction, is located on north of Qeshm island and 17 km west of Dargahan city. The power generation capacity of this plant is 500 MW. Also, besides the power plant, the med and RO desalination plants will be built. Seawater once through has been considered for power plant cooling system. In order to supply the intake water of the main and auxiliary combined cycle power plant cooling system, two units of med desalination plants with a total production capacity of 8,000 cubic meters of fresh water per day and RO desalination plant with a production capacity of 92,000 cubic meters of fresh water per day, a total of 1.2 million cubic meters of seawater per day is required. In order to obtain required water from the sea and discharge the return water into the sea, a proper intake & outfall systems should be constructed. Delta offshore technology is main contractor for endorsement, construction and installation of the seawater intake/outfall pipelines system. |

|

Client: IOEC/SADRA --- Status: COMPLETED |

|

Supply, transportation and injection of grouting material into annular space between the piles and pile sleeves to provide the load path for transfer of environmental loads from the structure to seabed and to maintain their integrity of platforms. Grouting operation contains: • Transportation of materials and grouting equipment |

|

Client: IOEC --- Status: COMPLETED |

|

Transportation and installation of approved backfilling materials around and on top of the two import pipelines after their installation. Each of the 32” sealines will carry 4.5” piggy-back line for transporting lean MEG (mono ethylene glycol) from the onshore facilities to the respective wellhead platform. |

|

Client: PMO --- Status: COMPLETED |

|

Dredging of port access channel (172,000 m3).

|

|

Client: R&T Ministry --- Status: COMPLETED |

|

As the seawater level decreased, all steel piles which were designed and constructed submerged, are exposed to splash zone.

|

|

Client: POGC --- Status: COMPLETED |

|

Construction of 129 m 2500 mm HDPE Storm Pipeline Construction of 129 m 1400 mm HDPE Outfall Pipeline These Pipelines were failed by previous Contractor |

|

Client: TTPC --- Status: COMPLETED |

|

Dredging of Seawater Intake (120,000 cubic meter)

|

| Client: NDCO --- Status: COMPLETED |

|

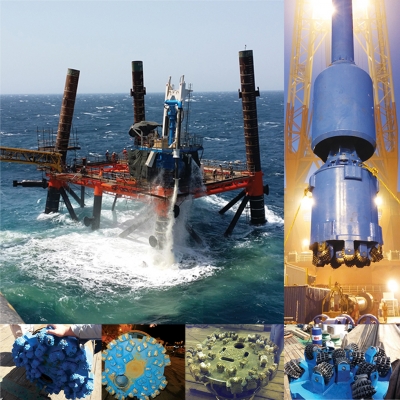

Amirkabir Semisubmersible Drilling Unit (AKSSDU) was designed and constructed to execute oil and gas exploration drilling operations in the Caspian sea. This semi-submersible drilling rig can operate at water depths up to 1,000 meters and drill down to 6,000 meters under the seabed. KEPCO has the mission of exploring Caspian sea to find oilfields and carrying out the corresponding drilling operations. Delta Offshore Technology is NDCO's subcontractor (the drilling contractor of KEPCO) to perform management, drilling operation, maintenance, provision and supply of professional key personal and highly qualified experts for on & offshore drilling operations of the Amirkabir semisubmersible drilling unit (AKSSDU) and other land or offshore drilling units. AKSSDU is currently located at a location with the distance of 250km from shore and water depth of 700m performing a discovery drilling operation. |

|

Client: NARDIS --- Status: COMPLETED |

|

Foroozan oilfield in the Persian Gulf is under reconstruction and renovation by the joint venture of Nardis-Arpa Group. This oilfield is located approximately 100km southwest of Kharg Island export terminal. Delta Offshore Technology (Delta) is cooperating with Nardis-Arpa Group JV as the installation contractor of two platforms in the Foroozan oilfield (FX and FY LQs). FX LQ, a 250ton living quarter, was installed on 30 th May 2011 successfully by Delta. FX LQ which is constructed in two floors provides accommodation for 21 person, a control room, a theater and a restaurant. All stages of FX LQ installation project including the Installation Engineering, Mooring Analysis, Anchor Handling Operation and Installation Operation was executed by Delta. FY LQ is a 750tons/3 floors platform which provides accommodation for 42 person. The installation engineering of FY LQ has been carried out by Delta Offshore Technology co. The installation operation of this platform will be executed in the future. |

|

Client: PPI --- Status: COMPLETED |

|

In order to supply seawater for cooling onshore facilities of South Pars Phases 19, located at south of Iran east of Kangan Port, a seawater intake systems is being developed by Petropars Iran. In this project, seawater will be collected at the basin through two 2m/length1200m high density polyethylene (HDPE) pipes. Delta Offshore Technology (Delta) accomplished the pre-engineering surveys such as hydrographic and sub-bottom surveys and geotechnical studies, basic and detail design, installation engineering, procurement, and construction and installation operations of the SPD19 seawater intake system. Similar to marine pipeline of the SP12 seawater intake system, herein ballasting weight of the pipelines will be provided by injecting grout inside the core-tube pipes inside the HDPE pipes. HDPE pipelines are fabricated onshore, towed to the location and installed using the float and sink method. |

| Client: PGSOC/SADRA --- Status: COMPLETED |

|

SADRA is developing the P.G Star Refinery seawater intake system. The project consists of installation of four 2.7m/length1300m steel pipelines. Delta Offshore Technology is cooperating with SADRA in executing the installation, engineering and management of the describe pipelines, which includes the following activities:

• Quality control procedure of the pipe strings • Floating pipe strings and relocating from fabrication yard to the installation location • Connecting strings of pipes together • Sinking the pipeline and installation at the designated location only in three days |

| Client: DAELIM-KAYSON-SAZEH JV --- Status: COMPLETED |

|

In order to supply seawater for cooling onshore facilities of South Pars Phases 12, located at south of Iran east of Kangan Port, a seawater intake systems is being developed by joint venture of Daelim, Sazeh and Kayson (DSK). In this seawater intake system, seawater is collected at the basin through two 2m/length1200m high density polyethylene (HDPE) pipes. Warmed discharge water returned to the sea using an approximately 200m length outfall HDPE pipe. Delta Offshore Technology (Delta) as one of the leading offshore companies in Iran accomplished the installation engineering, procurement, construction and installation operations of the offshore part of the SPD12 seawater intake system Seawater intake systems filter fishes and other particles in the seawater and collect only clear water from the sea floor, without installing structures which might affect the sea environment. In the seawater intake system the difference in water level causes seawater to flow into the intake pipe and collect clear seawater in the Sea water intake Basin at onshore. |

|

Client: IOEC --- Status: COMPLETED |

|

The objective of Phase 12 of the South Pars Gas Field development project is to produce gas and condensate for export. The offshore section is located some 100 km in the Persian Gulf, Iran, in approximately 70 m deep water and consists of 3 identical, 15 slots wellhead platforms (SPD 12A/B/C) and three 32inchsealinesfor transportation of 3 x 1000 MMSCFD of saturated gas and condensate to the on shore gas treatment plant, located in the Tombak area. A 30-inch line will be installed from the onshore plant to a Single Bouy Mooring (SBM) located near shore to export condensate. This project consists of receive, assemble, test, launch, tow and install two floating hoses of SBM. (Inner and outer lines 296 and 306 m respectively with range of different sizes from 16 to 24 inch). |

|

Client: IOEC --- Status: COMPLETED |

|

The objective of Phase 12 of the South Pars Gas Field development project is to produce gas and condensate for export. The offshore section is located some 100 km in the Persian Gulf, Iran, in approximate 70 m deep water and consists of 3 identical, 15 slots wellhead platforms (SPD 14/15/16) and three 32” sealines for transportation of 3 x 1000 mmscfd of saturated gas and condensate to the onshore gas treatment plant, located in the Tombak area. Each of the 32” sealines will carry 4.5” piggy-back line for transporting lean MEG (mono ethylene glycol) from the onshore facilities to the respective wellhead platform. A 30” line will be installed from onshore plant to Single Point Mooring (SPM) located near shore to export condensate (NGL). The scope of this project is supply, transportation and installation of approved backfilling materials around and on top of the three export pipelines and SBM pipeline after it has been installed. |

|

Client: SADRA --- Status: COMPLETED |

|

The South Pars gas field is located in the Persian Gulf at 100km off the Iranian Southern Coast. National Iranian Oil Company (NIOC) is developing Phases 13 of the field, which will allow a gas production of 2000MMSCFD. The project consists of installation engineering for: • Two 32" export pipelines (each with a 4" piggyback line transporting mono-ethylene glycol (MEG)) of 1000MMSCFD capacity each. • Two 18" infield pipelines (each with a 4" piggyback line transporting mono-ethylene glycol (MEG)) of 500MMSCFD capacity each. |

|

Client: IOEC --- Status: COMPLETED |

|

The South Pars Facilities are developed to produce gas and condensate from the South Pars Field, located offshore, some 130 km of Tombak, Persian Gulf, Iran. National Iranian Oil Company (NIOC) is developing South Pars Phase 14 of the Field, which will allow a gas Production of 2000 MMSCFD. This phase will have four wellhead platforms equipped with required production facilities. Platform design production capacity is 600 mmscfd and Platform normal production rate is 500 MMSCFD. This Project consists of supply and safely operation of pile top drilling facilities for pile driving of SDP14D & SPD14B field jacket installation project, where a premature refusal has been predicted by geotechnical site investigation report using the hammers. |

|

Client: SAFF --- Status: COMPLETED |

|

Supply, transportation and injection of grouting material into annular space between the piles and pile sleeves to provide the load path for transfer of environmental loads from the structure to seabed and to maintain their integrity of platforms. Grouting operation contains: • Transportation of materials and grouting equipment • Taking of grout samples for laboratory testing • Measurement the appropriate water/cement ratio. • Mixing of water and cement in two steps • Injection of grout extensively into jackets legs with relevant equipment • Control of applied grout pressure with laboratory tools |

|

Client: SADRA --- Status: COMPLETED |

|

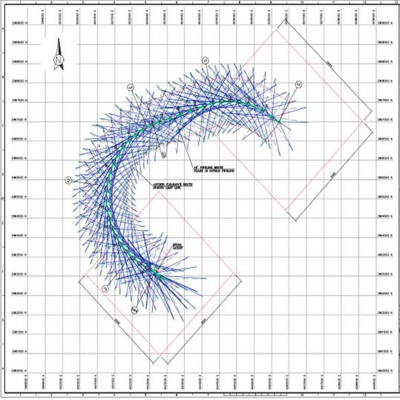

The South Pars Facilities are under development to produce gas and condensate from the South Pars Field, located at 105 km South West of Assaluyeh in the Persian Gulf, Iran. National Iranian Oil Company (NIOC) is developing South Pars Phases 17 and 18 of the Field, which will result in gas production of 1,000 MMSCFD per phase. The project consists of installation of two new infield pipelines, including 7.4Kmx18” between SPD25 and SPD24 and 19.4Kmx20" between SPD26 and SPD23 for transferring of 2x500MMSCFD row offshore products in the South Pars Gas Field (Phase 17/18). To offer the best overall engineering solution to Pars Oil and Gas Co. and Deep Offshore Technology Co., Delta Offshore Technology did the best solution for the Infield Pipeline Installation Engineering of the South Pars Phase 17/18. Delta Offshore will act as leader of the joint venture where it will effectively manage as one single front end engineering team to fully deliver and bring about the successful and timely delivery of the Infield Pipeline Installation Engineering Project. |